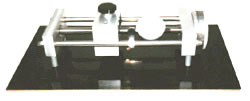

| printable version | Ballspindle | |

| Ballspindles are used to improve the properties of a normal spindle drive with respect to reduction of friction and increase of speed. Ballspindles are very important elements in the drives of toolmachines. They compete today with the direct magnetic drive. The accuracy does not only depends on spindle and nut it also | |

| depends on the bearing of the locked spindle end. To reduce play, the baring and nut can be adjusted stiffer. But not to forget is the fact, that a certain play is simply necessary for lockfree running under temperature expansion. So all this is a question of clean adjustment. This model was made to train this aspects. | ||

Description: The model has got a loading device in the form that a slide can be differently pressed against the traversebolts. The spindledrive now has to overcome the more resistance, the stronger upper and lower slide are screwed together. The handwheel has got the scaling 250. This corresponds to the spindle gradient 2.5 mm The dial gauge 5mm/0.001mm is set axially against the spindlenut to measure play. |

||

Experiments:

|

||

| ©TeLC Unna 2004 | ||